3.5″ Sunlight Readable IPS Display, 320×240, 850 Nits with Capactive Touch Panel Air bonded

-

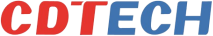

S035HQ55ES-DC37

-

3.5"丨320 x 240 Pixels

-

IPS with All viewing angle

-

Capactive with l²C interface

-

24-bit RGB

-

I2C

-

-20°C~+70°C

Product Description

Introducing the CDTech 3.5-inch IPS LCD display, boasting a stunning 320 x 240 pixel resolution for crystal-clear visuals. coupled with a fully laminated capacitive touchscreen, offers seamless interaction and a full-viewing angle for optimal user experience.

With a typical brightness of 850 nits, this display shines bright even in direct sunlight. Compatible with RGB LCD and IIC capacitive touch interfaces, it performs reliably in temperatures ranging from -20 to 70 degrees Celsius, making it versatile for various environments. Choose CDTech for your display needs, combining cutting-edge technology with robust durability.

Product Specification

| LCD Size | 3.5 inch |

| LCD Resolution | 320*240pixels |

| LCD Active Area | 70.08 x 52.56 (mm) |

| LCD Luminance | 850nits |

| LCD Viewing Angle | IPS with All viewing angle |

| LCD Interface | 24-bit RGB |

| LCD Controller | ST7272A |

| LCD Connection Type | FPC: 54PIN with 0.5 pitch ,Connector : FH12-54S-0.5SH |

| LCD Backlight Array | 3 Strings with 3 LED on each string |

| LCD Backlight Controller | None |

| LCD Backlight Driving | IF =60mA ,VF =9.6~0.6V |

| LCD Outline Dimension | 76.90 x 63.90 x 3.26 (mm) |

| CTP structure | G+G |

| CTP interface | I2C |

| CTP Controller | GT911 |

| CTP Outline Dimension | 76.90 x 63.90 x 0.7 (mm) |

| CTP Connection Type | FPC: 6PIN with 0.5 pitch |

| Product Outline Dimension | 76.90 x 63.90 x 4.89 (mm) |

| Product Operation Temp | -20°C~70°C |

| Product Storage Temp | -30°C~80°C |

Recommendations for use

-

LCD Customization

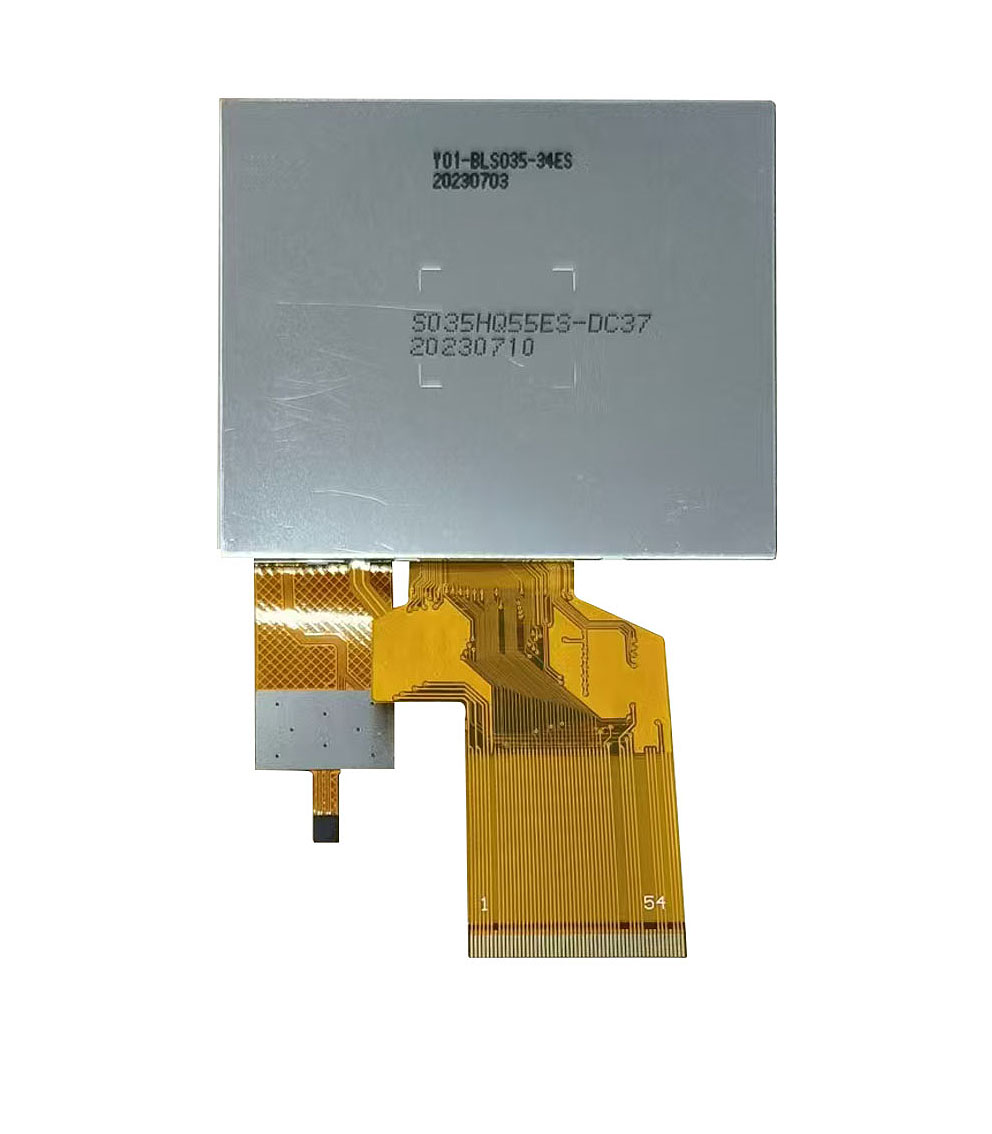

LCD FPC is both an important part of the LCD module and a key choice for customer motherboards. CDTech can support customized FPC pinout layout, overall dimensions, FPC with connector type, soldering or plug-in type, PWM function design, anti-static design, EMI, EMC, ESD, and black epoxy resin coating around the IC. Most of the automotive projects have extreme requirements for the EMI, EMC, ESD, in order to help customers minimize EMI, EMC, ESD issues, we can add EMI shielding film to the FPC.

-

Touch Panel Customization

For TFT+CTP solutions, CDTech can support air bonding, OCA bonding and LOCA bonding. For TFT+cover glass(no touch), most customers prefer OCA bonding. However, CDTech can also help evaluate the feasibility of using air bonding or LOCA bonding and provide professional advice.

-

Usage Guidelines

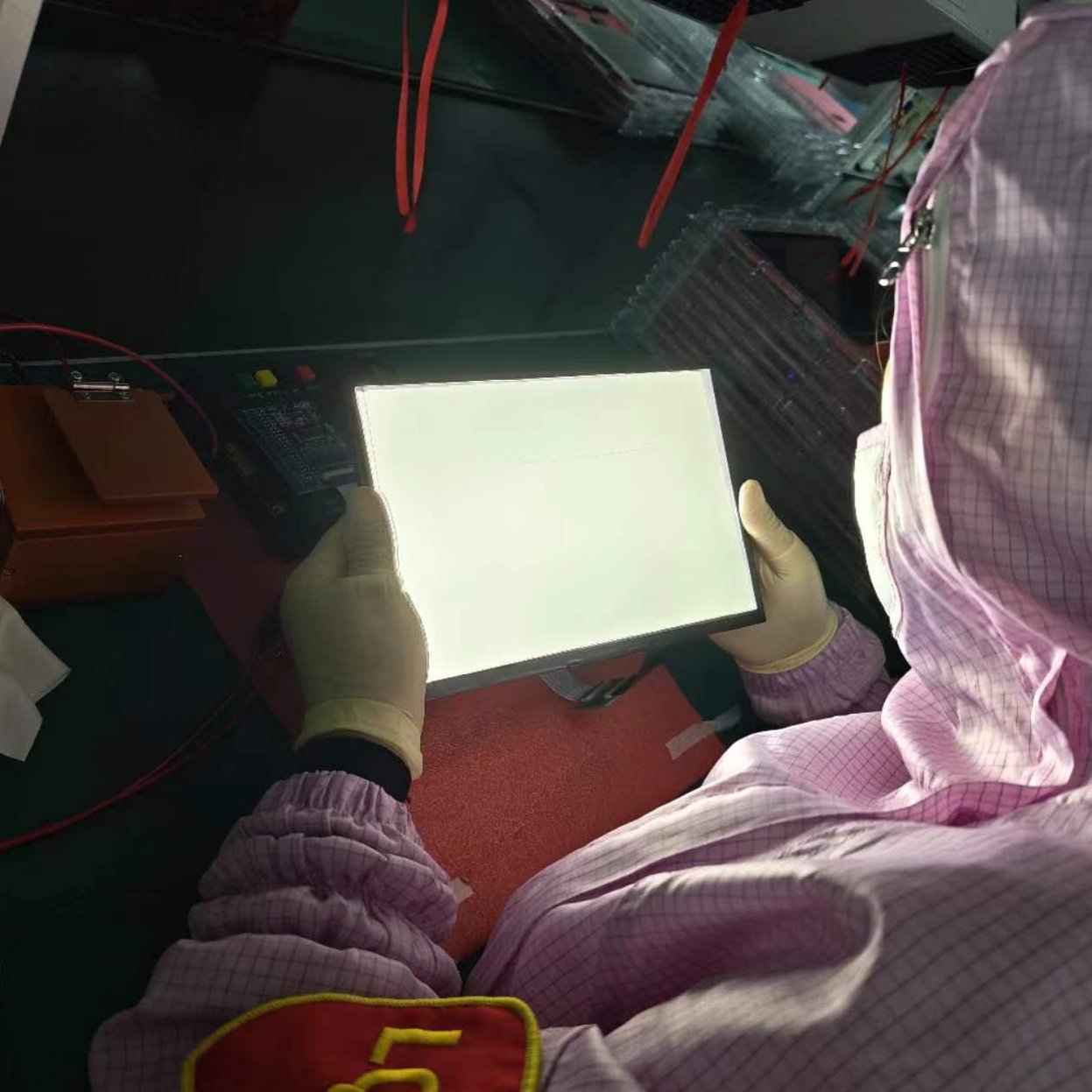

CDTech’s LCD products have high quality reliability, allowing customers to use them for a long time without easily breaking down. However, we also suggest that customers will follow the correct operation or storage methods when using them: try to avoid direct contact with the FPC gold fingers with hands to prevent oxidation. It is recommended to wear anti-static gloves or finger cots for operation, and ensure effective grounding. When the products are not used for a long time, they should not be stored in high-temperature and high-humidity environments for a long time, but should be stored in a warehouse with appropriate temperature and humidity.

Quality Standards

CDTech adheres to a Zero Defect Quality Policy, which includes not only product quality but also the work quality of all departments in the company. This will make our products, quality, service, and technical support exceed your expectations.

All of our products, from evaluation, design, production, inspection to after-sales service, follow the following standards in the process.

| Project Evaluation |

Comprehensively and accurately understand and evaluate customer requirements, including performance, specifications, usage environment, special characteristics, safety characteristics, etc. Identify and evaluate potential risk factors. |

| Product Design |

Strictly follow the requirements of ISO9001 and IATF16949 systems for product design, while also considering material selection, manufacturability and assemblability, past successful product structures and experiences to ensure effective implementation in subsequent production. In the sample stage, verify according to the reliability test requirements in the specification. |

| Production Control |

All important processes of LCM and CTP are produced by CDTech itself, ensuring effective control and assurance of the production process. Strictly follow the production process to ensure that each operation meets established standards, select high-quality raw materials that meet specification requirements, and ensure the stability of product performance. |

| Production Inspection |

All CDTech products have undergone 100% functional testing and visual inspection to ensure that they meet design requirements and customer expectations. |

| After Sales Service |

We have established a rapid response mechanism to promptly handle customer feedback and complaints. Usually, we can reply to customers within 1 day about the possible causes of defects and temporary measures, issue a defect judgment report within 3 days of receiving the defective product, and issue an 8D analysis and improvement report within 7 days. |

| Product Lifetime |

The lifetime of our product is determined by the lifetime of the LED in the backlight, usually 30000 hours or 50000 hours. Please refer to the specifications for details. |

| Warranty period |

The warranty period of CDTech is one year according to LCD industry standards. Within one year, any product with any problems can receive free after-sales service and returns. After one year, CDTech can still provide paid after-sales service. |

| ESD Protection |

All devices are designed and handled in consideration of ESD protection. This includes ESD-SAFE packaging within anti-static bags, wraps, and trays. Customers are reminded to always follow ESD safety to best protect the devices. |

-

7F, Bldg 2, Jiancang Technology Park, No.11 Songgang Blvd., Baoan, Shenzhen