How Industrial LCD Screens Enhance Operational Efficiency

The Role of Industrial LCD Screens in Modern Operations

Importance of Visual Displays in Industrial Settings

In settings having visual aids is crucial for ensuring seamless operations by linking complex systems with human users to facilitate efficient communication and organization tasks driven by the increasing demand for screens as technology progresses prompting manufacturers to continuously improve their products to align with changing consumer needs in sectors where accuracy and clear communication play vital roles.

Key Features of Industrial LCD Screens

Durability and Robustness

In settings are often tough to work in due to issues like dust and extreme temperatures making things difficult at times but industrial LCD screens are built tough to handle these challenges ensuring they last long and perform reliably.

High-Resolution Display Capabilities

In settings where accuracy is key and intricate details matter most. Like overseeing intricate procedures or examining data. Having high quality images on screens is crucial for making informed decisions with precision and clarity at the forefront of it all. CDTech stands out globally with its cutting edge patent and technology by providing specialized LCD screens tailored to meet the evolving demands of innovation.

Improving Workflow with Industrial LCD Screens

Streamlining Communication and Data Sharing

LCD screens used in industries help in improving communication by showing information and updates on the factory floor directly to workers which helps them in making quick decisions based on informed choices thereby enhancing the efficiency of overall workflow process significantly.These screens serve as a platform for sharing data which helps in removing any obstacles and in turn boosts productivity levels within the workplace.

Enhancing Monitoring and Control Systems

Real-time Data Visualization

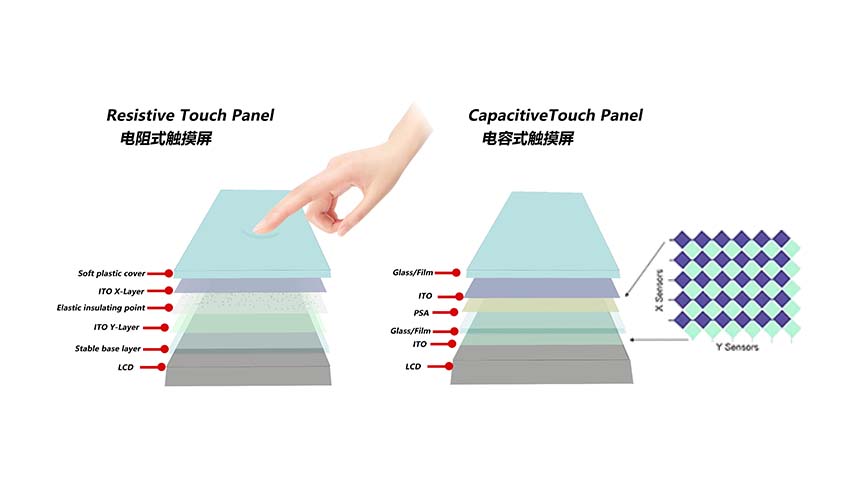

In environments real time data visualization has a significant impact by enabling operators to monitor processes constantly and react swiftly to any irregularities that may arise. LCD technology functions by positioning crystal material between two conductive glass layers to facilitate precise management of light transmission for precise data depiction.

Interactive Interfaces for User Engagement

Interactive interfaces found on industrial grade LCD displays captivate users with their user controls and responsive features which in turn elevate the overall user experience and streamline system administration processes resulting in enhanced operational efficiency.

Energy Efficiency and Cost-Effectiveness of Industrial LCD Screens

Reduction in Power Consumption

Energy efficiency plays a role in industrial processes because it affects both expenses and environmental sustainability factors significantly. The latest industrial LCD screens are engineered to function at peak performance with power consumption leading to substantial long term savings.

Longevity and Maintenance Benefits

The durability of LCD displays decreases the necessity for frequent replacements and leads to substantial savings on maintenance expenses over time.CDTech’s products offer enduring value and dependable performance that align with objectives.They deliver top-notch and budget friendly solutions tailored to various industry needs.

Utilizing cutting edge technologies like the ones created by CDTech enables industries to boost their effectiveness with better visual presentations that provide durability, clarity, energy conservation and user interaction features. These advancements not simplify processes but also support eco-friendly practices across different industries worldwide.

Integration of Advanced Technologies with Industrial LCD Screens

Compatibility with IoT and Smart Systems

The incorporation of LCD with IoT and intelligent systems represents noteworthy progress in contemporary industrial practices. These displays are crafted to link up with a variety of devices and platforms facilitating efficient data transfer and system administration. This interoperability guarantees that industrial operations are more interconnected, enabling monitoring and management from distant sites. With industries transitioning towards automation and digital transformation the significance of LCD screens escalates in bolstering these technologies.

Customization Options for Specific Industry Needs

Industrial LCD screens provide a range of customization options to meet the unique requirements of various industries. These screens can be adjusted in size. Equipped with specialized features to suit specific operational needs. CDTech excels in customizing LCD displays and touchscreens to ensure their products perfectly match customer expectations. This level of customization enables industries to enhance their workflows by incorporating displays tailored to their applications.

CDTech: Leading Innovations in Industrial Display Solutions

Overview of CDTech’s Product Range

Advanced LCD Screens with Integrated Boards

CDTech provides a variety of LCD screens with built-in boards that boost their performance and functionality levels. They are crafted to offer top-notch display resolution while being energy efficient and suitable for use.The incorporation of boards enables connectivity and enhanced processing power enabling support for intricate tasks in multiple industries.

Other Cutting-edge Display Technologies

CDTech is leading the way in developing not advanced LCD screens but also other state of the art display technologies that cater to specific industry requirements with their patented 2nd CUTTING technology for unique sized LCD displays.

By embracing these technologies and innovations in the field of industrial LCD screens allows industries to unlock the complete potential for improving their operational efficiency significantly.At CDTech, we prioritize durability, visibility, with energy efficient features and engaging user experiences for our products that are set to revolutionize modern industrial processes globally.

FAQ

Q: How can industrial LCDs endure challenging circumstances?

A: Industrial LCD displays are manufactured with designs that incorporate elements such as resistance to dust and water and anti glare coatings to withstand a wide range of temperatures from 30°C to 80°C effectively ensuring dependable operation in challenging settings such, as factories or outdoor locations.

Q: What sets LCD screens apart in terms of durability compared to commercial displays?

A: They incorporate materials like aluminum frames and tempered glass along with innovative backlighting such, as LED or high brightness panels to withstand vibrations and shocks while ensuring prolonged functionality.This helps minimize downtime and cuts down on replacement expenses.

Q: Can industrial-grade LCDs be connected to automation setups seamlessly?

A: Certainly! Here is the paraphrased text; Indeed! Many industrial LCDs are compatible with protocols such as Modbus and CAN bus or Ethernet/IP. This allows for linkage with IoT platforms and SCADA systems, for real-time data visualization to aid in predictive maintenance and process enhancement.

Q: How can industrial LCDs enhance energy efficiency in operations?

A: Functions such, as brightness adjustment and energy saving modes help reduce power usage while ensuring clear visibility even in well lit surroundings to promote sustainable practices effectively.

Q: What should I keep in mind when selecting a display screen, for use specifically an LCD screen?

A: Important aspects to consider are the ratings (IP65/IP67) visibility under sunlight (at least 1000 nits) type of touch technology (capacitive/resistive) integration with current control systems and adaptability, for potential future enhancements.

2025-03-13

2025-03-13  11:50

11:50