Comprehensive Guide to Fixing Common Industrial Display Problems

Identifying Common Display Issues

Screen Flickering and Distortion

The issue of screen flickering often arises due to reasons like loose connections or incompatible drivers and is characterized by sudden changes in brightness or color on the display screen. Distortion refers to anomalies in image clarity, like blurriness or misalignment of elements.

Check that all cables are plugged in and check for cable damage if you want to solve flickering problems. Driver updates are also recommended when there are compatibility issues that may cause the screen to flicker. Make sure the display settings match the screen resolution to take care of any distortion issues.

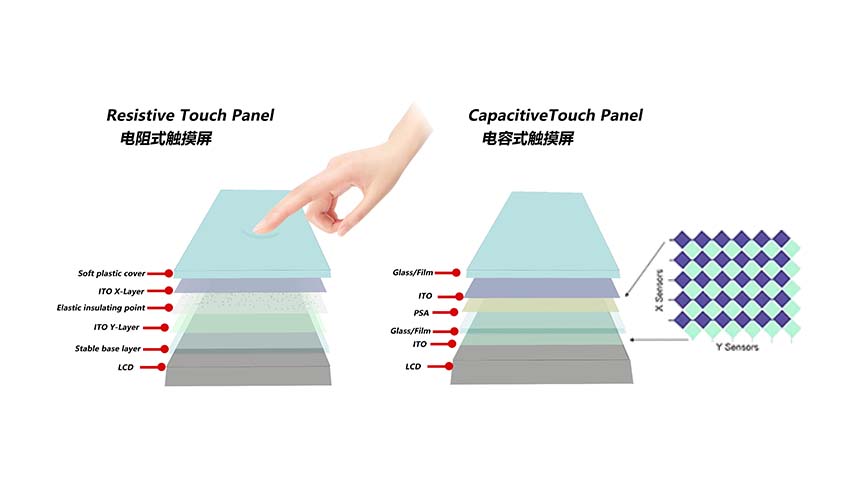

Unresponsive Touchscreens

It can really take the wind out of things when a touchscreen isn’t responsive. This could be due to the fact that the display has been damaged physically or some software bugs messing with the touch sensing or just because there is dirt and stuff accumulated on the display that ruin the touch registration.

To begin with, the first step in this process is to wipe the touchscreen with a cloth to remove dirt and stains. Otherwise, perhaps play with the control panel or software settings on your device to try to resolve it. The exception is if you have damaged the screen though. Consider replacing it with a touch panel, such as the well-functioning and solid CDTech TPC 1500 series.

Troubleshooting and Maintenance Techniques

Keeping displays functioning well and minimizing the need for repairs can significantly extend their lifespan.

Basic Troubleshooting Steps

If you come across any problems with the screen display. Firstly check if all power connections are secure and make sure all cables are correctly plugged in. Try restarting the device as this can often fix small software hiccups that may be affecting the display quality.

When dealing with issues such as screen flickering or unresponsiveness on your display screen at home or work it’s helpful to consult the manufacturers guidelines for troubleshooting tips that are customized for your particular model of monitor or TV screen. Make sure to make use of tools that are offered directly from the manufacturer as they can be quite useful in pinpoint any possible hardware problems in a timely manner.

Regular Maintenance Practices

It’s important to perform maintenance on industrial screens to ensure they remain in top notch condition.Clean the screens regularly using cleaning products to prevent the accumulation of dirt that might impact visibility or touch responsiveness.

Regularly check the cables and connectors for any wear or damage. Replace them as needed to keep the connections between components stable. Make sure the ventilation openings are clear to avoid overheating which may cause component failure in the run.

Taking precautions like setting up surge protectors can help shield against spikes that could harm delicate electronics found in screens such as CDTech’s rugged monitors with an IP65 rating specifically created for challenging environments where shielding from outside elements is essential.

Understanding the elements of industrial display systems recognizing typical issues at an early stage implementing efficient troubleshooting methods and maintaining them consistently will boost performance reliability and prolong the lifespan of products. This will guarantee operational efficiency in a wide range of industrial settings. Leveraging CDTech’s product line, such as the OPM 1900 open frame monitors provides customized solutions to meet specific industry needs effectively without compromising on quality standards expected in professional environments worldwide now and in the future.

Advanced Solutions for Persistent Problems

Replacing Faulty Components

When problem-solving techniques and upkeep efforts prove ineffective in addressing ongoing problems with industrial displays it may be necessary to replace defective parts. It is essential to pinpoint the component that is causing the trouble. For example, if a display persists in flickering after ensuring all connections are secure and updating drivers the root of the issue might be within components, like the controller board or backlighting system.

When it comes to swapping out these parts for ones it’s best to rely on the skills and accuracy of experts in the field Or seek help from certified service providers for replacement work, CDTech offers a variety of replacement parts such as control boards and backlighting specifically crafted to match their line of screens guaranteeing a smooth fit and full functionality restoration.

Upgrading Display Systems

Sometimes it might make financial sense to replace the entire display system instead of constantly fixing old technology that’s no longer up to par. In industrial environments technological progress brings better features that boost performance and dependability. Switching to a newer version can bring advantages like sharper visuals enhanced touch capabilities and increased energy efficiency.

CDTech provides cutting edge display options such as the RDM 2400 series displays that come with top notch technology to endure harsh conditions while offering exceptional visual quality. It is believed that adopting these models can greatly improve effectiveness and lower maintenance expenses in the long run.

Enhancing Display Performance

Optimizing Display Settings

Fine tuning the appearance settings is a yet impactful way to boost productivity and comfort levels at workstations. Fine tuning brightness levels and adjusting contrast and color settings can enhance visibility. Minimize eye strain for individuals spending extended periods in front of screens. Keeping display settings in sync with the screens resolution helps avoid distortion and preserves the sharpness of images displayed on screen.

To enhance the responsiveness of displays you can tweak the touch sensitivity settings. By going into the control panel on your device you can customize these settings to suit your specific operational requirements. The TPC 2100 Series touch panels from CDTech provide interfaces for convenient adjustments guaranteeing top notch performance across different industrial uses.

Implementing Protective Measures

Preserving displays for an extended period relies heavily upon implementing protective measures to shield them from harm effectively. Installing covers or enclosures serves as a barrier against damage and keeps screens safe from dust and moisture infiltration. This precaution is especially crucial in environments where displays face conditions that could compromise their longevity.

Screen protectors are great for keeping your screen scratch free and reducing glare to make it more durable and easier to read. Also remember to control the temperature to prevent problems that could damage the display in the long run. CDTech’s IP65 rated enclosures offer defense against environmental dangers and are perfect for tough industrial settings.

FAQ

Q: If my industrial monitor screen flickers on and off what steps should I take to address the issue?

A: First have a check on all the cable connections if they are firmly held in their places, then check them for any external damage. Download and install drivers if needed to ensure they are compatible with your system setup. If the flickering is still going on after considering these points, consult a technician who can check things like the controller board or backlight for faults.

Q: How can I make the touchscreen more responsive on my monitor?

A: Clean the screen first clearly, if any dust or dirt shows the touch cannot work properly. You could also re-calibrate the touchscreen via the control panel or software interface on the device. If these actions do not solve the issue, you may require the replacement of the touch screen with a high-grade touch display available in the market such as the CDTech touch panel TPC 1500 series.

Q: When would it be an idea to update my industrial display system?

A: When your current system needs repairs or is missing advanced features that could boost efficiency it might be time to think about upgrading it to access better technology with improved performance metrics such as higher resolution and energy efficiency benefits, like those seen in CDTech’s RDM 2400 series rugged displays designed for tough environments.

Q: What maintenance routines should I follow to take care of my screens properly?

A: Keep cleaning your screens because, with the cleansing solutions, dirt can build up and may reduce your view or screen contact sensitivity rate. Inspect cables for wear marks or damage Replace them when necessary. Keep air vents free and clear, or it’s gonna cause problems. Steps such as the use of a surge protector too can protect sensitive electronics found in displays such as CDTech’s IP65 rated monitors specifically designed for harsh environments.

2025-03-25

2025-03-25  11:50

11:50