Capacitive Touch Panel or Resistive: Which Suits Your Needs?

Exploring Touch Panel Technologies

Differences Between Capacitive and Resistive Panels

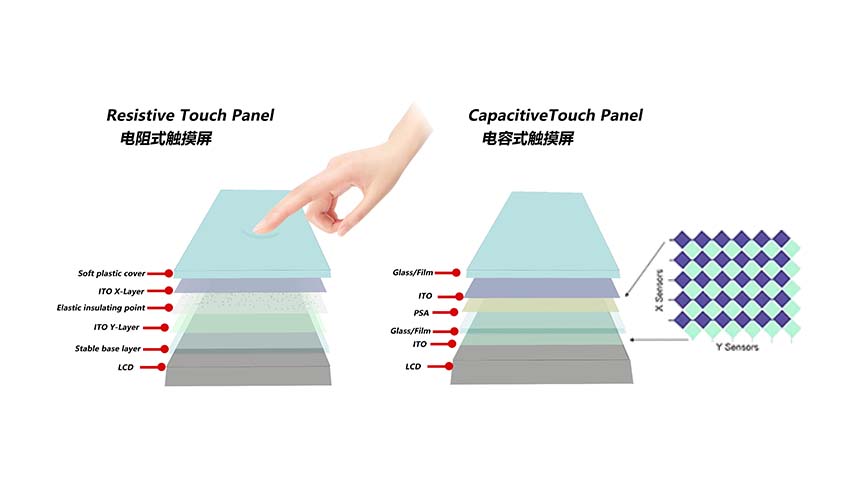

In the realm of touch panel technologies, understanding the differences between capacitive and resistive panels is crucial for selecting the right type for specific applications. Capacitive touch panels operate by detecting changes in capacitance when a conductive object, such as a finger, comes into contact with the screen. This technology is known for its high sensitivity and multi-touch capabilities. In contrast, resistive touch panels rely on pressure applied to the screen, which causes two conductive layers to make contact. This method is generally more affordable but lacks the precision and responsiveness of capacitive panels.

Key Features of Capacitive Touch Panels

Capacitive touch panels are renowned for their superior sensitivity and accuracy. They support multi-touch gestures and offer a smooth user experience. CDTech provides capacitive touch panel customization services that include thick cover lens support, waterproof operation, glove touch functionality, and compatibility with active or passive pens. The flexibility in selecting different IC solutions ensures that these panels meet diverse application requirements.

Characteristics of Resistive Touch Panels

Resistive touch panels are characterized by their reliance on physical pressure to register input. They are typically more cost-effective and can be operated with any object, including styluses or gloves. CDTech offers resistive touch panel solutions that maintain reliable performance across various environments. While they may not match the sensitivity of capacitive panels, resistive panels are valued for their robustness and simplicity in certain use cases.

Performance and Usability Factors

Sensitivity and Accuracy Comparison

When comparing sensitivity and accuracy, capacitive touch panels generally outperform resistive ones due to their ability to detect light touches and support multi-touch gestures. CDTech’s capacitive panels provide precise touch functionality essential for applications requiring high accuracy. On the other hand, resistive panels offer adequate performance where basic interaction suffices.

Durability and Maintenance Considerations

Durability is a significant consideration in choosing between these technologies. Capacitive touch panels from CDTech are designed with robust materials that withstand long-term use without degradation. The EMI design effectively reduces electromagnetic interference, ensuring stable signal transmission even in sensitive environments. Resistive panels also offer durability but require careful handling to avoid damage from excessive pressure or sharp objects.

Environmental Suitability for Each Type

Environmental factors play a critical role in determining the suitability of each panel type. Capacitive touch panels excel in environments where precise control is necessary, such as industrial settings where EMI reduction is crucial. Their ability to function with gloves or under wet conditions makes them ideal for automotive or medical applications. Conversely, resistive panels perform well in scenarios where users may wear gloves or need a cost-effective solution without sacrificing reliability.

Application Scenarios for Each Panel Type

Industrial and Commercial Uses

In industrial applications, capacitive touch panels are preferred due to their high sensitivity and ability to operate under challenging conditions. CDTech’s products ensure reliable performance with features like thick cover glass support and waterproofing, essential for industries such as automotive manufacturing or industrial control systems.

Consumer Electronics Applications

For consumer electronics, capacitive touch panels dominate due to their sleek design and responsive user interface capabilities. Devices like smartphones and tablets benefit from the multi-touch functionality provided by CDTech’s customized solutions that enhance user experience through intuitive interactions.

Specialized Use Cases

Specialized use cases often dictate the choice between capacitive and resistive technologies based on specific needs. For example, medical devices might favor capacitive panels for their precision in data entry under sterile conditions using gloves. Alternatively, public kiosks might opt for resistive technology due to its resilience against heavy usage by diverse users.

By evaluating these factors—sensitivity, durability, environmental suitability—and considering application-specific requirements, stakeholders can make informed decisions when choosing between capacitive and resistive touch panel technologies offered by CDTech’s extensive range of customizable solutions.

Cost Implications and Market Trends

Price Analysis of Capacitive vs. Resistive Panels

When considering the cost implications of touch panel technologies, it’s essential to analyze the pricing differences between capacitive and resistive panels. Capacitive touch panels generally come at a higher price point due to their advanced technology and enhanced features like multi-touch capability and high sensitivity. In contrast, resistive touch panels are more budget-friendly, making them an attractive option for projects where cost is a significant factor. CDTech’s range of capacitive touch panels reflects this pricing trend, offering premium solutions with customization options that justify their investment through long-term reliability and performance.

Current Market Trends in Touch Panel Technology

The current market trends in touch panel technology indicate a growing preference for capacitive touch panels across various sectors. This shift is driven by the demand for user-friendly interfaces that support complex gestures and provide a seamless interaction experience. CDTech is at the forefront of these trends, offering capacitive touch panel solutions that cater to diverse applications, from industrial control systems to consumer electronics. The company’s ability to customize touch screens for specific use cases ensures that it remains competitive in an evolving market landscape.

Future Developments in Touch Panel Technology

Innovations in Capacitive Touch Panels

As technology advances, innovations in capacitive touch panels continue to emerge, enhancing their functionality and application scope. One notable development is the integration of more sophisticated IC solutions that improve touch accuracy and responsiveness. CDTech collaborates with leading IC suppliers to incorporate cutting-edge technologies into their capacitive panels, ensuring they meet the highest standards of performance and reliability. Additionally, advancements in materials and design structures, such as G+G or GFF configurations, contribute to increased durability and user satisfaction.

Emerging Trends in Resistive Technology

While capacitive technology leads the market, there are emerging trends in resistive technology that address specific niche requirements. Innovations focus on improving the durability and pressure sensitivity of resistive panels, making them suitable for environments where ruggedness is paramount. CDTech’s commitment to providing reliable resistive solutions ensures that they remain relevant in applications where cost-effectiveness and robustness are critical factors.

CDTech’s Role in the Touch Panel Industry

Overview of CDTech’s Product Offerings

CDTech plays a pivotal role in the touch panel industry by offering a comprehensive range of products tailored to meet various application needs. Their portfolio includes both capacitive and resistive touch panels, each designed with unique features to cater to specific market demands.

Other Types of Products Offered by CDTech

Beyond touch panels, CDTech provides an array of other products that complement their core offerings. These include customized LCD modules with options for different backlight types, anti-reflective coatings, and specialized cover glass designs. The company’s expertise extends to creating fully custom solutions that incorporate advanced technologies like EMI reduction for enhanced compatibility with sensitive electronic devices.

CDTech’s dedication to innovation and quality assurance positions it as a leader in delivering high-performance display solutions tailored to customer specifications. Whether it’s through their state-of-the-art capacitive touch panel offerings or robust resistive alternatives, CDTech continues to set benchmarks in the industry by addressing diverse technological challenges with precision-engineered products.

2025-01-07

2025-01-07  11:50

11:50